Chapter-8

Postings in Executive management level

First posting at Danapur--From Assistant Engineer/Dhanbad I was promoted as Divisional Engineer and posted at Asansol. But before I was relieved there was an unexpected development and a revised order was issued for my posting at Danapur. My placement near the hometown of Ara was life affirming for my parents.

No less delighted were wife’s parents as father-in-law was then posted as Station Master, Patna Jn.

Bungalow no 177 DEF allotted to me had no room for the trolley men. They remained in the premises of my predecessor who had taken over as DPO. I had to depend upon his courtesy to get the services of the trolleymen during unforeseen development. The railway hospital was very near to my residence. But there was only one multipurpose shop on the north side on Khagaul-Danapur road. For major purchases a visit to Khagaul bazar (on the south of the yard) or Patna was necessary. An Anglo-Indian lady ran a private school for the kids in the premises of the N.C.Ghosh institute next to the station.

My section started from Mughalsarai extending to Dehri-on-Sone on the Grand Chord and further to Garhwa road on the CIC section. The UP GC between Gaya & MGS carrying very high density of traffic was laid with 65 kg/m Russian imported rails on wooden sleepers in 5-rail panels, box-anchored to arrest creep. A higher section of rail has never been used on the Indian railways. It was a matter of pride for me that the biggest marshalling yard of MGS equipped with mechanized hump & retarders & the then longest rail bridge (Upper Sone bridge) between Dehri-on-Sone & Sonenagar, consisting of 100 spans of 100 ft length each , belonged to my section. Side plates were provided on this girder bridge in the recent past to retain ballast profile for a higher ballast cushion on the trough plates supporting track structure. On a 7 years painting cycle it was necessary that some 30 spans are painted every year during 6-7 months working period. It was not an easy task for the AEN. The ballast quarry near Karwandia station was a good source of supply, served by a siding taking off from this station.

My section started from Mughalsarai extending to Dehri-on-Sone on the Grand Chord and further to Garhwa road on the CIC section. The UP GC between Gaya & MGS carrying very high density of traffic was laid with 65 kg/m Russian imported rails on wooden sleepers in 5-rail panels, box-anchored to arrest creep. A higher section of rail has never been used on the Indian railways. It was a matter of pride for me that the biggest marshalling yard of MGS equipped with mechanized hump & retarders & the then longest rail bridge (Upper Sone bridge) between Dehri-on-Sone & Sonenagar, consisting of 100 spans of 100 ft length each , belonged to my section. Side plates were provided on this girder bridge in the recent past to retain ballast profile for a higher ballast cushion on the trough plates supporting track structure. On a 7 years painting cycle it was necessary that some 30 spans are painted every year during 6-7 months working period. It was not an easy task for the AEN. The ballast quarry near Karwandia station was a good source of supply, served by a siding taking off from this station.

Ara station did not figure in my jurisdiction, but I had the satisfaction of being near it and watching it while proceeding from Danapur to Mughalsarai for inspection. Only 4 wheelers pooled carriages to be attached to passenger trains , were available for inspection.

Danapur division had came into being in 1925. About a month before my joining Sri S.N.Sachdev, who was my DS while at Dhanbad, had taken over as DS/Danapur. Sri R.K.Banerjee transferred from the post of Divisional Superintending Engineer to Dy DS at Danapur itself had little time to oversee the affairs of the engineering department. The chambers of the DENs located on the 1st floor were deprived of natural light & ventilation due to presence of verandah on one side and the office on the other. Indicator lamps were available outside the chamber of some officers. For others, the table peon attached red or green hand signal flag outside chamber in the slot provided for this purpose. The indicator lamp of the DS had a repeater signal on the 1st floor also. The engineering control was manned by an inspector from operating department and was called Ballast train supervisor. The division was recuperating from the aftermath of the flood. So far I was accustomed to working with an independent office. Working in a divisional headquarters was a new experience. Everyday on entering the office, I first visited the engineering control to get the details of incidents (rail failure, water supply failure, train detention on engineering account, blocks for engineering works) concerning my section. It was followed by taking feedback from the field units so as to be in readiness to answer the query of the DS. It is only after going through these formalities, that one could think of settling down to routine works. In early December 1971 India had joined the Bangladesh liberation war. There were frequent blackouts and sirens. Whenever a military special passed through Danapur, it stopped for some time when DS with officers and staff attended them and offered bouquets and items of daily use to the personnel. After the war was concluded, the Pakistani prisoners-of-war had to be repatriated. One day I saw a train load of the POWs at Dehri-on-Sone station. Sri R.K.Banerjee was deputed to proceed to Bangladesh to help the Indian army in restoration of the track and bridges damaged in the war. Restoration of the Hardinge bridge over Padma river was a formidable task for him.

But sorrowfully it was a short-lived posting as I was booked for a 3 months course on ‘Advanced work study’ at the Railway staff college , Baroda. Work study is a management technique that analyzes work processes to improve efficiency and productivity. It encompasses method study, which focuses on optimizing work methods, and time study, which establishes standard times for tasks. Job monitoring, often a part of work study implementation, involves tracking performance against established standards and identifying areas for further improvement. It was a useful course .During the long training period at Baroda, my group, which included DEN/ER, DSTE/ER, DME/SR and DCS/Madurai, was allotted the project of ‘Catering system on the Southern Railway’. The CCS was very happy. Naturally we received the best cooperation from the officers & inspectors of the commercial department. During our visit to different catering units (including the godown at the heritage Royapuram station) and while attending meetings at the S.Rly headquarters we were served with highly tasty coffee prepared with suitable proportioning of seed A, seed B and Chicori. I have never had a better tasting coffee in my life since then. To fulfil our assignment we stayed at Madras Egmore station rest house for about a month. The restaurant at Madras Central was the destination for our meals. During my visit of Chennai Central in 2011 it was a disappointment that the historic restaurant on the first floor was decrepit and forlorn.

As Efficiency Officer/E.Rly , Calcutta--. After return from Baroda, I was posted as Efficiency Officer, Eastern railway, Calcutta in 1972. It was a sequel to my having undergone training in Advanced work study. A Flat was allotted to me in Liluah railway colony. It was situated on the Gardiner road which opened towards the G.T. road. The railway club, the railway hospital, the railway institute with a badminton court and a small park were the attractions of the colony which was primarily designed for the officials and staff of the Liluah workshop. The cinema hall was on the other side of the railway yard. Belur Math, the headquarters of Ram Krishna mission, was not far from this locality. This was my first posting in a headquarters office. A railway bus carried us daily to our office at the Fairlie Place picking officers of the Colvin Court, Howrah on the way. The Efficiency organization, comprising of officers and inspectors from different departments, was tasked with study of work situations and making recommendations for their improvement. The themes were proposed by the HODs and selected ones approved by the GM on a yearly basis. Some of the subjects for study included, ‘Accountal & documentation of loco coal’, ‘Durgapur steel exchange yard’, ‘Coaching terminal facilities at Patna Jn’, ‘Howrah goods shed’ ,‘Suburban services in Calcutta area’ and ‘Break-of-gauge transshipment . Apart from Sr DGM, we were guided by Dy CME (RL) and Dy COPS (Goods). The task allotted for work study necessitated movement all over the Eastern railway . A monthly report was sent to the Director Efficiency Bureau , Railway Board. My controlling officer (Sr DGM) allowed me to visit Bombay for a week to study the suburban rail system both on the Central Railway and the Western Railway. During this period I was accommodated at Churchgate station railway rest house, from where I could watch hundreds of suburban locals calling at this station and retracing back making use of 3 lines only.

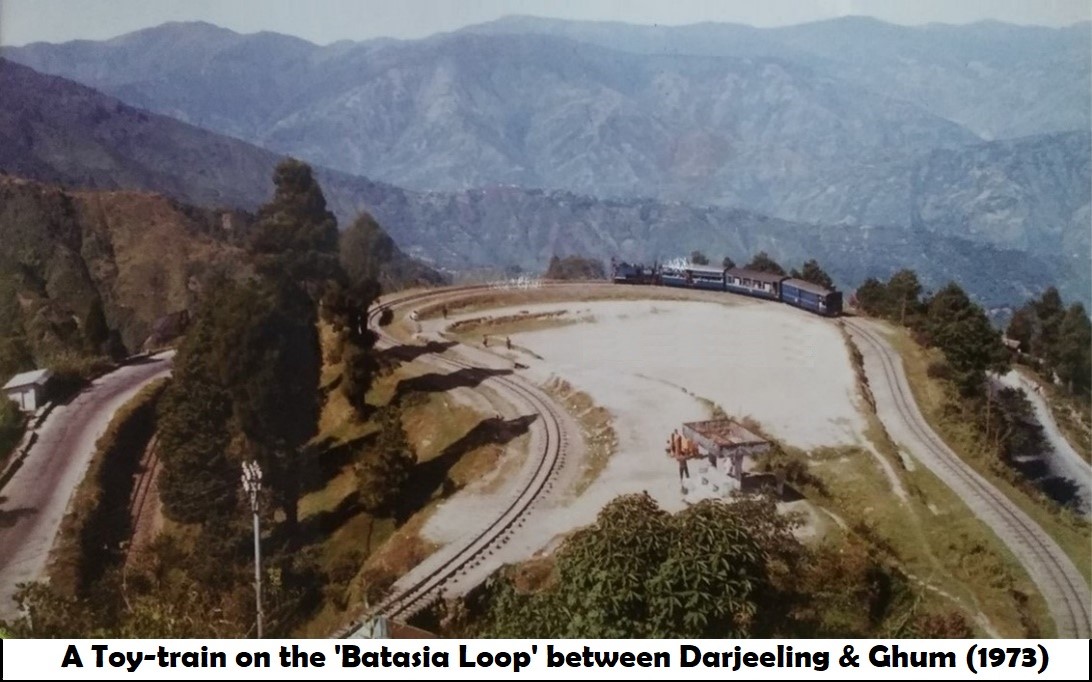

While in this post, a trip to Darjeeling materialized. The Eastern railway has a rest house ‘Craigmont’ at this hill station whose booking was convenient from the headquarters. From Howrah to New Jalpaiguri (then junction of BG, MG & NG) it was an overnight train journey by Darjeeling mail. Darjeeling Himalayan Railway (gauge 2 ft) runs from New Jalpaiguri to Darjeeling. It uses six zig zags and three loops to gain altitude of 2100m ,taking the passengers across verdant hills revealing rolling tea gardens, cascading streams and charming hamlets. The train was hauled by a puffing steam engine overcoming the resistances imposed by sharp curves and steep grades. Two fellows sat on the smokebox platform of the loco sprinkling sand on the rail top table to provide adhesion of wheels to the rail. Tindharia is a quaint station known for its loco shed. Kurseong is an important station, being hub of the railway's operations and administration. Ghum (5 kms before Darjeeling) is the highest altitude station beyond which the train negotiates Batasia loop. Here the track spirals around over itself from the bottom of a small hill and over the hilltop and almost imperceptibly undergoes very sharp descent. The loop complex was non-descript those days but today it offers stunning views of a poignant war memorial of dedicated Gorkhas , an obelisk and a delighting flower garden .

The toy train took about 7 hours to cover a distance of 88 kms, but it was a relaxed and charming journey through the picturesque mountain.

.

Makaibari and Lopchu are both tea estates in Darjeeling, that produce high-quality tea. Makaibari tea is known for its unique flavor, while Lopchu tea is known for its smoky, woody character

Though shaken initially, I enjoyed the Hqrs posting except for some anxious period during the railway strike of 1974 sponsored by the NCCRS (National Coordination Committee for Railwaymen Struggle) demanding ,inter alia, grant of bonus for railwaymen. I had to move out to work as an Emergency officer at Gaya and Dehri-on-Sone. I availed of this posting to visit the international borders (i) between Gede (India side) & Darshana (Bangladesh side) and (ii) Petrapole (India side) & Benapole (Bangladesh side). Gede & Petrapole stations had came into being after partition on logistic consideration. During pre-partition days the Dacca Mail ran between Sealdah and Goalundo ghat (via Gede on India side & Darshana on Bangladesh side), wherefrom the passengers were ferried to Narayanganj on the outskirts of the city of Dacca. The Barishal Express ran between Sealdah and Khulna (via Petrapole on India side and Benapole on Bangladesh side).

Second posting at Danapur-- In the next transfer somewhere in mid 1974, I was posted as Divisional Engineer/Danapur for the second time. Sri M.K.Sinha, a mechanical engineer, was the DS. Bungalow no 104 was allotted to me in this posting. The trolleymen were Ram Surat, Jeetan, Rambilas and Sheomuni. They were all smart and very much attached to the children. Sections of AEN/Gaya and AEN/Dehri-on-Sone were under my charge .The familiar 65 kg-wooden sleepers track on the Up GC, otherwise performing well, was developing non-cyclic wear on rails requiring interchange of gauge faces & hand greasing, Extra keymen were deputed on Phalgu bridge (UP GC) for tightening fittings on steel channel sleepers. Water supply problem arose in CIC section in summer months. Japla was an important station where infiltration gallery was made in the river bed to tap subterranean water. Yet we had to source water from ‘Japla cement’ which pumped Sone river water for its work. Soon after joining I felt enormous pressure for reinstatement of the staff removed from service in the recently concluded railway strike. The situation was rendered more trying due to J.P. movement threatening to disrupt rail services. I had to frequently camp at Gaya for coordinating with the D.M. (K.A.H. Subramaniam) and the S.P. (A.K.Pandey). The N.C.Ghosh Institute named after erstwhile COPS was popular amongst staff. The Mahila Samity also functioned from here. The Railway club was a place for social gathering of the officers on Saturdays and special occasions. There was a swimming pool also in its premises. The Rest house was a part of the club complex. HOD visiting the division was normally invited for lunch and dinner at the official residence of the concerned Branch officer. However, GM and Sr DGM were entertained in the club.

The DS had a strong inclination for his own department. During the punctuality meeting the DME/Power alleged that due to presence of oily content in the water supplied to the locos at MGS ‘Priming’ used to occur. As a result, the locos could not pick up speed. The DS acquiesced to it but this was unacceptable to us. Finally, it was decided that the water sample would be sent to Jamalpur workshop for testing. There used to be bank slips in Tal and Rampur Dumra links (not in my section). But if the sectional DEN happened to be on leave during the monsoon period, I had to remain alert apprehending a call to attend the restoration work. Sri A.N.Wanchoo, also a mechanical engineer, succeeded Sri M.K.Sinha. Sri Wanchoo said ‘there were many items of works required for loco shed and C & W depot. As DME I was unable to get them done by the DEN. But as DS, I am in a better position.’

3 UP Howrah-Bombay Mail (via Allahabad) had derailed at Shivsagar road in Gaya-Mughalsarai section. There was no dispute as to the cause which was ‘seizure of the roller bearings’ of a particular coach. What intrigued the enquiry committee was the fact that the train running at about 100 kmph went off the rails near the east cabin and could be brought to a halt near the west cabin causing minimum damage to the track. The cabinmen, the ASM and the guard all wanted to take the credit for promptly attracting the attention of the driver about the mishap to enable him to apply brakes. But the enquiry committee was not convinced. Finally, the driver was taken into confidence. He solved the mystery by admitting that he was in the habit of chewing tobacco even while on duty. It so happened that by a strange coincidence he happened to open the cab door near the east cabin for spitting when he noticed the track ballast flying all over and an unusual sound. He promptly applied the brake and could stop the train near the west cabin.

One late evening, I was asked by the Divisional Superintendent to attend an accident in Dhanbad division The accident site was in Gurpa (lower end)- Gujhandi (higher end) ghat section between Dhanbad & Gaya. Earlier a goods train had derailed on the UP Grand Chord (GC). Crane was brought from Gaya on the Down GC. The wagons (5 nos) were rerailed and kept on the Down GC. The crane having accomplished its task was ordered to proceed to Gaya on the Down GC. Upto this stage everything went fine. Then came the anxious moment. A loco was brought on the Down GC from Gujhandi (higher end) to pick up the rerailed wagons. But the gunner due to error of judgment failed to connect the coupling. On the other hand, the impact of the loco set the wagons in motion. By the time the mistake was realized the wagons had moved substantially and soon became irretrievable. Impelled by the steep downgrade, the runaway wagons gathered momentum. There was no catch siding at Gurpa. Nothing could be done. The wagons were finally halted only when they smashed the Gaya bound crane and its occupants at a speed of about 120 kmph. Things were transformed into smithereens. Over 2 dozen railwaymen were killed/injured in this tragedy. It was the second such accident I had to attend.

Sri K.N.Dasgupta (Additional Chief Engineer, Calcutta) had arrived at Mughalsarai for inspection. His return programme was by Rajdhani express arriving Mughalsarai at midnight. Before boarding the train, he asked me to set my watch correctly to second according to his and directed that I should remain on the footplate. Whenever I felt lurch, I should note down the location as well as the time. He remained in the First AC coach. The purpose was that whenever awakened from sleep due to bad riding he would note the timing and arrive at the location by comparing his notes with mine, which would include timing as well as location. In the morning at Dhanbad I handed over my notes to him. He was apparently satisfied.

There was a tour to the colonial hill station of Mussoorie, some 35 kms from the nearest railway station of Dehradun. We had put up in the railway rest house named ‘Duggal villa’ from where we enjoyed the Himalayan views and undertook outings to the Mall known for its shops and restaurants.

Eastern Railway Women’s organization- it shows solicitude for railway persons and their families. Various social welfare schemes have been launched under its aegis for general upliftment of women specially the female employees and children of the railway personnel. It endeavours to make them self sufficient.

As Dy Chief Engineer (Plant Depot), Mughalsarai--From DEN/ Danapur I was promoted and posted as Dy CE/PD/ MGS in February 1977. It is an engineering workshop fabricating bridge girder, platform shelters, footoverbridges. The bridge girders were passed by the RDSO. On permanent way side points and crossings and glued insulated joints were manufactured. But there were problems in their assembly awaiting supply of fittings from the stores department. At the Flash butt welding plant 13m rails received from Bhilai steel plant were welded into 10 rail panels in the A I Welder, imported from England. Rail ends positioned with a small gap were heated because of electrical resistance using high amperage at low voltage. They burnt with flash and at appropriate temperature pressed longitudinally resulting in their fusion. After chipping off excess metal from the top table and the gauge face and subsequent grinding they were loaded on special purpose wagons and dispatched for use at the worksite.

Beginning in sixties track machines were progressively introduced on the E. Rly. starting with the procurement of Plasser & Theurer make tamping machines . Plasser India then set up its factory at Faridabad (Delhi) for manufacturing multiple types of track machines with imported/indigenous components. These machines were powered by diesel engines and transmission of power was hydraulic. Accordingly spares for the diesel engines, hydraulic pumps and tamping units were required to be arranged from different sources. The operation and maintenance of the entire fleet of the E.Rly. were looked after by the Plant Depot. There was a Ferro-concrete yard also for casting footoverbridge slabs, small-span R.C.C. bridge slabs and washable aprons. Accounting--Raw materials received were charged to Capital suspense 9500 . Materials issued against shop orders were charged to Workshop manufacturing suspense 9700 crediting Capital 9500. In turn Capital 9700 was credited after supply of finished product. Taking guidance from the Jamalpur workshop I had prepared a paper on the ‘Incentive scheme’. But this did not find favour with the Hqrs. Emergency tools and plants meant for restoration of bridges damaged in accidents/floods were stored in its premises. The wooden piles & the pile driving equipment procured years back were of doubtful use in the changed situation. There was also a Calender Hamilton span -a modular, portable, prefabricated Warren truss-for use as emergency replacement of bridge of different spans. This is how this engineering workshop derived its name. The Foremen & the Chargemen were all mechanical engg diploma holders but borne on the engineering cadre. Managing a production unit with a large workforce (about 1200) in a confined area ,while meeting targets was a complex experience with a mix of challenges and rewards. My Executive Engineer, Shri Sharat Kumar Sinha was an outstanding engineer and a conscientious manager. I used this posting to invite the GM (Sri S.N.Sachdev) during his visit of the workshop to plant a sapling of KADAMB -a fast growing and wide spreading evergreen tree enjoying a worthy place in mythology and folklore.

Accounting--Raw materials received were charged to Capital suspense 9500 . Materials issued against shop orders were charged to Workshop manufacturing suspense 9700 crediting Capital 9500. In turn Capital 9700 was credited after supply of finished product. Taking guidance from the Jamalpur workshop I had prepared a paper on the ‘Incentive scheme’. But this did not find favour with the Hqrs. Emergency tools and plants meant for restoration of bridges damaged in accidents/floods were stored in its premises. The wooden piles & the pile driving equipment procured years back were of doubtful use in the changed situation. There was also a Calender Hamilton span -a modular, portable, prefabricated Warren truss-for use as emergency replacement of bridge of different spans. This is how this engineering workshop derived its name. The Foremen & the Chargemen were all mechanical engg diploma holders but borne on the engineering cadre. Managing a production unit with a large workforce (about 1200) in a confined area ,while meeting targets was a complex experience with a mix of challenges and rewards. My Executive Engineer, Shri Sharat Kumar Sinha was an outstanding engineer and a conscientious manager. I used this posting to invite the GM (Sri S.N.Sachdev) during his visit of the workshop to plant a sapling of KADAMB -a fast growing and wide spreading evergreen tree enjoying a worthy place in mythology and folklore.

As Sr Divisional Engineer/ Mughalsarai- I was the first incumbent to this post .The new Division was carved from Danapur division. Before its formation another Sr DEN was posted at DNR to look after the affairs of the proposed division. The files were allotted the suffix of ‘ML’ or ‘GC’ depending on whether they were to be retained at Danapur or transferred to Mughalsarai. The Division had not yet firmed up. Some posts were still to be created and the sanctioned posts were still to be filled. Sri S.N.Jha (my predecessor as AEN/Gomoh), happened to be my DEN. With his technical and managerial skill he proved to be an asset to me. Sr DOS gave blocks for MGS yard lines in turn but in the matter of blocks on the GC for on-track tampers he was hesitant. In some cases the AEN imposed speed restriction on stretch of track overdue tamping. Welding of stock-rail-joint and lead-rail-joints improved running on Points & Crossing. It was only when I got a letter to offer remarks on people demand to set up a coach factory at Saidraja that I came to know about a large parcel of railway land at ‘Saidraja brickfield siding’. The open channel (provided with hume pipes for small length at inlet) carrying the run-off of yard & colonies to Ganga was not performing well. Hence the hume pipes were removed. 10 days PCDO was sent to the CE apprising him of achievement & failures during the period and specifying the matters on which assistance from the headquarters was solicited. The Advisor (Vigilance), Railway Board had come to MGS. While addressing the officers he remarked, ‘There is nothing I can do and you cannot do better’. My posting as Sr DEN/MGS lasted for 2 years. During 4 years stay at MGS we made a trip to Nainital. It was a train journey by 5 UP to Lucknow followed by an overnight journey to Kathgodam in a MG train. Onward journey to Nainital, some 34 kms away, was by bus. The stay was arranged at the railway’s rest house. Naini lake is major attraction of the town and is one of the most visited lakes in India.

Advanced permanent way course at IRICEN, Pune – It was a 10 weeks course which was overdue for me. Handing over the charge to Sri S.N.Jha, now promoted as Sr DEN, I proceeded to Pune and set my feet for the first time at IRICEN’s newly constructed hostel at Koregaon Park. The institute functioned from the same historic building next to the station. Sri Yashwant Patwardhan was the Principal. I had also the pleasure of receiving lessons from Sri L.C.Jain and my batchmates viz Prof. M. Mani and Prof. G.R.Madan.

Rail-wheel interaction, realignment of curves, design of hump, curved switch, elastic fastenings were interesting topics. While on the subject of Long Welded Rails & Continuous Welded Rail we were told that theoretically the rails could be welded to any length and laid with specially designed joint ( Switch Expansion Joint), because the expansion and contraction of the rail panels, irrespective of length, occurred only in the end 100 metres or so. However from the practical point of view it is desirable to lay them as LWR in the lengths of one km to facilitate their yearly destressing for their proper functioning even in extremes of temperatures. Use of heavier section of rails (60 kg/m), PSC sleepers ( 250 kg each) , large ballast cushion (300 mm) and requirement of laying & maintaining track to rigid tolerances leave no choice but to rely on mechanized laying & maintenance . The types of track machines in use/proposed to be inducted on the Indian railways include :-Laying-(i) Plasser Quick Relaying System (PQRS)- It consists of self propelled portal cranes which move on auxiliary track of 3400mm gauge having the same centre line as that of the track to be relayed, without infringing movement on the adjacent lines. Capable of self loading & unloading from BFRs these cranes can lift a 13m long panel fabricated with new sleepers & service rails. (ii) Track Relaying Train is a complete mechanization of track renewal process with superior quality of track produced. (iii)Points & crossing changing machine. Maintenance-Tamping-lining-levelling machine (UT, Unomatic, Duomatic, CSM) ,Points & crossing tamping machine, Ballast cleaning machine, Ballast regulating machine, Dynamic track stabilizer, Special purpose-Rail grinding machine, Mobile flash butt welding machine.

To fulfil the criteria of track safety and comfort following instruments have been inducted into the system. (i) Track recording car-They use contact type sensors or LASER based contactless sensors to record track parameters needed to define track geometry. (ii) Oscillograph cars-They are used for monitoring riding quality of the track by recording vertical and horizontal accelerations of the vehicle.(iii) Portable accelerometer-They measure the track performance by recording vertical and horizontal accelerations by converting the oscillations of the vehicle into electrical signals which are recorded electronically and processed on the PC. The data recorded during above instrumented runs are analyzed to determine riding quality, maintenance requirement and possible track deterioration. The engineers must adapt themselves to the new work culture for reasons such as consistency, quality, improved safety ,enhanced productivity & optimum resource utilization.

During course of lectures, there were frequent reference to UIC (Union Internationale des chemins de fer) which is an International Union of Railways with its headquarters at Paris. It aims at promoting rail transport at world level and setting standards. Every trainee was required to present a paper on a subject from the list furnished by the Principal. Mine was ‘Criteria for realignment of curves’. A formal report was submitted to the Institute after return to the respective railway.

There was also a trip to Ernakulum to see bridge foundation work in a backwater for construction of Ernakulam-Alleppy new line. While we stood on the steining of the half completed well, the site engineer cautioned us and asked us to hold the reinforcement rods firmly ,as the well may suddenly go down for some depth in the treacherous soil.

The Advanced PWay courses aimed at fostering a culture of continuous learning was beneficial as it offered specialized knowledge of principles & practices of PWay engineering including track layout , track fittings, track-modernization and track-vehicle dynamics. It also equipped us with skills crucial for track laying and maintenance using the latest track technology and address challenges .